Stabilplastik

Leader in the Reuse of Plastic Waste

The question of how to use plastic waste repeatedly, meaningfully and sustainably has plagued Europe for a long time. While in some countries the issue of plastic waste recycling is already very well researched, in others, for example in the Czech Republic, plastic waste mostly ends up in landfills or incinerators. Stabilplastik set itself the task of changing that. The Company produces plastic transport pallets from plastic waste, which have a number of advantages over wooden ones.

20 years ago, the company’s founder and current managing director, Jan Suchopár, came up with the idea of producing pallets from recycled plastic.To this end, in the 1990s, he gained experience abroad, where the issue of reusing plastic waste had already been very well researched.

Recycling vs. Incinerating

For the production of plastic pallets, Stabilplastik uses secondary mixed plastic waste (plastic bottles from detergents, table oils, lids from plastic bottles, etc.) and from industrial waste, specifically in the form of polyethylene and polypropylene. Generally, this is a kind of plastic that cannot be used in injection molding technologies and which today usually ends its life cycle prematurely. Unlike manufacturers using injection molding technologies, Stabilplastik‘s products contain exclusively recycled mixed plastic and the proportion of primary material components is essentially zero. According to estimates by various institutions and waste companies, in the Czech Republic about 70–80% of the volume of plastic waste ends up in landfills and, to a lesser extent, in incinerators.

The use of this waste for the production of plastic pallets allows for its effective, repeated recycling, saving both primary resources such as wood and clean plastics, and efficiently diverting waste from landfills and incinerators. In addition, production is waste-free. All material inputs as well as overflows from production are transformed into new products.

Sustainable Origin and Operation

Transport pallets made of recycled plastic have a number of advantages over conventional, wooden ones – first and foremost, their sustainability and the environmental friendliness of their use. Stabilplastik takes damaged pallets from customers and use them 100% as material input to production. Based on the LCA study (life cycle study of the pallet and its material), it was found that the company’s Euro pallet (80×120 cm, 25 kg weight) has about 74% lower impact on the environment than wooden pallets.

The benefits of using recycled plastic pallets are also recognized by companies in day-to-day operations. One of them is their resistance to weathering and the resulting longer service life. The product’s resilience is also related to resistance to insects, fungi and most common acids, and the consequent suitability for export. In addition, pallets do not need to be stained or heat treated as opposed to wooden ones.

Other significant advantages include dimensional stability, which is essential for the use of pallets in automated lines and warehouses where the slightest deviation of dimensions due to protruding chips or nails means not only a huge safety risk, but also financial losses caused by the need to stop operations and clean the line from such defective pallets.

Last but not least, hygiene is another big advantage. The pallets are easy to wash and do not absorb any dirt from the surroundings. With wooden pallets, no one can guarantee what has been stored on them and for how long, or whether they release dangerous substances that may have exuded onto them during storage.

Technologies to Reduce the Carbon Footprint

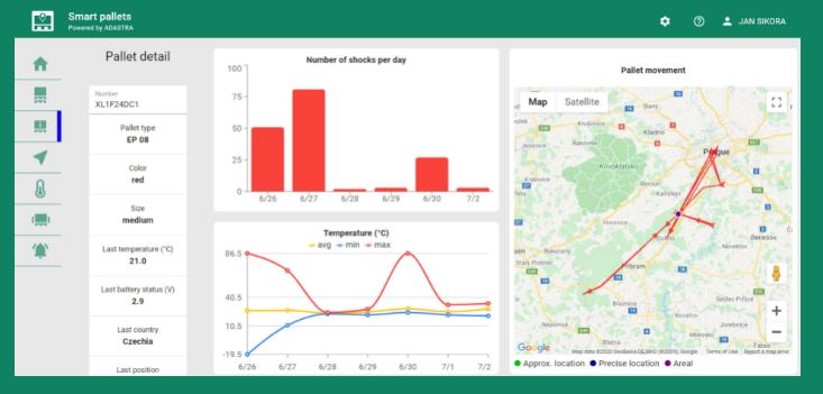

Stabilplastik has recently launched a so-called “smart pallet”. It is equipped with a chip that monitors not only the position of the pallet, but also other variables individually defined by customers, such as pallet occupancy, shocks, ambient temperature and others. Equipping the pallet with a chip leads to an even longer use of secondary plastics, because its movement is consistently monitored and the pallet can thus be used to the very limit of its physical capabilities. The pallet does not have to lie idle anywhere and can be extracted very efficiently. At the same time, the data allows companies to analyse the efficiency of freight transport and adjust its routes to reduce the carbon footprint and the overall environmental burden of transport.

Smart pallets are minimally energy intensive. The battery will keep the chip running for about five years. At the end of its service life, the chip or pallet can be replaced and further used. The SigFox technology used allows the Company to significantly reduce the energy intensity of this solution compared to GPS monitoring.